New ASTM Standard Expected to Boost PP Piping Systems

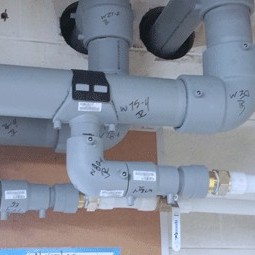

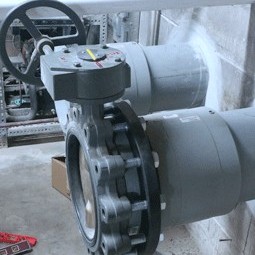

Borealis PP random copolymer is present in some important North American plumbing and industrial PP piping projects, such as the installation of Nupi Americas NIRON PP-RCT in the existing elderly-care facility Wesley Willows Senior Living Center in Rockford, Illinois. NIRON PP-RCT was used for hydronic installation to re-pipe an ageing system and to replace a cooling tower and other equipment. From small plumbing installations to large industrial piping systems, with an innovative PP random copolymer with improved temperature resistance, Borealis Group and NIRON PP-RCT are expected to get a lot of play in North America, thanks to a new ASTM standard. Pressure-rated PP piping systems have long been standardized in other parts of the world, and have built up a solid track record over the past 30 years. Borealis has used its ‘Value Creation through Innovation’ strategy to develop and pioneer new PP-RCT solutions for exceedingly demanding pipe applications for North American market requirements. Compared to conventional materials like steel and copper, NIRON PP-RCT reportedly offers significant advantages. The new ASTM F2389-17a Standard makes it easier for North American engineers and builders to select thermoplastic piping systems as replacement solutions for traditional materials. Advantages of thermoplastic piping systems like PP-RCT include: thermal fusion joining, leak-tight pipe fusion, high corrosion resistance, easy installation and minimal maintenance, long lifetime with improved environmental impact, downgauging potential and higher hydraulic capacity than traditional PP-R.