NUPI TAKES PART IN THE INNOVATIVE TORS PROJECT

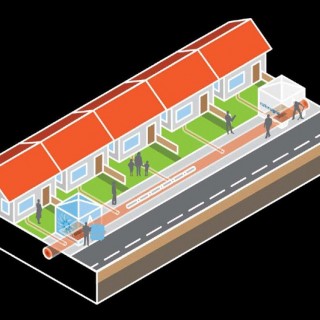

NUPI Industrie Italiane is very proudly taking part in the innovative TORS project - Tier One Replacement System - with its ELOFIT electrofusion fitting. The TORS project was designed to develop a robotic system to allow the replacement and remote connection of services to mains. The robotic system is made up of various units, each with its own specific task. At present, saddle fittings have been developed that can weld polyethylene pipes with a diameter of 75mm and 90mm. The project started in 2012 and the first replacement dates back to April 2017. The ultimate aim of the project is to design and develop a robotic system that is capable of remotely undertaking 10 services to main connections on a 100-meter section of main with only two excavations, eliminating the need for service excavations in the public with significant cost savings and time and vehicle traffic reduction. The TORS project therefore starts downstream of the insertion of a polyethylene pipe inside the main metal pipe (in cast iron or steel) to be decommissioned. The task of the robot, once inserted into the new polyethylene pipe, can be summarized as follows:

- locate the existing connection;

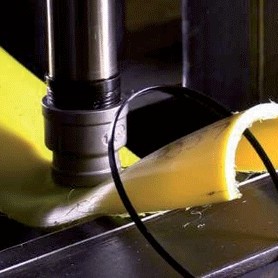

- drill the polyethylene pipe;

- position and weld an electrofusion saddle fitting on the inner surface of the new polyethylene pipe;

- insert the new polyethylene branch line inside the domestic connection from;

- welding the fitting on the branch line;

- carry out a test to verify the welding.