Welding systems

NUPI offers a wide range of junction systems: spigot joining, joining through electrical heater plate (butt fusion) and electrofusion welding.

Welders for spigot jointing are equipped with an aluminum heater plate and a handy thermally insulated plastic handle for small diameters. For diameters between 2 "and 5" instead, the machine is equipped with a removable frame with side handles that facilitates positioning and transportation.

Welders allow welding of PE, PP, PP-R and PVDF elements and are characterized by different shapes and working areas according to specific needs.

Our welding units for electrofusion fittings are available for diameters from ½" to 24" and are equipped with optical scanner, integrated GPS system and USB output for data download.

In addition, the new generation of NUPI welding units stands out not only thanks to their design, but also thanks to their safety and innovation!

Practical and safe 'PELI' welding units are incorporated in waterproof, watertight transport cases resistant to rigid temperatures (mostly PELICASE).

SMART welding units, also incorporated in transport cases, are associated with NUPI APP, which allows complete management of all information about site, welding, traceability of installed products, mapping of the installation by GPS location and all subsequent testing activities.

All electrofusion welding units are also available in a light version (low weight and practical use).

SOCKET WELDER WITH SUPPORT

POLYFUSION SYSTEM

- description

- details

Manual socket welders joining pipes and fittings. They feature an aluminum heating plate and a practical, heat-insulated plastic handle. They can weld HDPE, PP, PP-R, PVDF pipes and fittings, and they’re characterized by different shapes and working ranges, suitable for different applications.

The machines unclude: Socket welder - Fork support - Bench vice (except NSBEP) - Allen wrench - Pin for sockets & spigots

| MODEL |

NSBEP/110 |

NPCCE/110 |

NPCCE125/110 |

|---|---|---|---|

| Nominal size range (IPS) | 1/2" ÷ 1" |

1/2" ÷ 2" |

1/2" ÷ 5" |

| Power supply | 110V - 800W | 110V - 1400W | |

| Dimensions | 4.5"x1.9"x 14.2" H | 6"x1.4"x 14.2" H | 6.8"x1.9"x 15.5" H |

| Weight | 3.170 lb | 4.010 lb | 8.820 lb |

| Working temperature | 500°F (± 32°F) | ||

| Outside temperature range | 23°F ÷ 104°F | ||

| Die pairs bushings | included | not included | not included |

Male/Female die pair bushings for welder

| CODE |

Size |

Weight (lb/p) |

|---|---|---|

|

MATRICE20 |

1/2" |

0.242 |

| MATRICE25 | 3/4" | 0.330 |

| MATRICE32 | 1" | 0.506 |

| MATRICE40 | 1" 1/4 | 0.726 |

| MATRICE50 | 1" 1/2 | 1.056 |

| MATRICE63 | 2" | 1.386 |

| MATRICE75A | 2" 1/2 | 2.020 |

| MATRICE90A | 3" | 3.080 |

| MATRICE110A | 4" | 5.140 |

| MATRICE125A | 5" | 4.880 |

SOCKET WELDER MACHINE

POLYFUSION SYSTEM

- DESCRIPTION

- DETAILS

STL125L/110 Welding machine LIGHT is a field machine for socket welding method, for pipe and fittings in HDPE, PP, PP-R, PVDF, PB for diameters included between 2" ÷ 5". Leading particulares are the restricted weight, minimum overall dimensions and versatility.

Featuring: a machine body, a self-centring clamp for locking the pipes, a self-centring clamp for locking the fittings, an extractable socket welder with an automatic electronic temperature, fitting holder and a special bench vice so the machine can be used on a work bench.

STL125/110 This workshop/construction site welding machine is suitable for the socket fusion of pipes and fittings up to 5". It is composed of a machine body featuring a selector for the welding depths of the different diameters, four self-centering steel clamps for locking pipes and fittings (different brands), a self-centring socket welder with electronic temperature control, a device for the maximum heating depth, a sliding trolley, a tripod to support the pipe, a set of sockets and spigots for socket fusion from Ø 3/4" to 5" with steel case.

The machine includes: Machine body with an electronic socket welder - Steel case complete wtih socket ad spigots from 3/4" to 5" and tool kit - Pipe support tripod - Sliding trolley - Die pairs bushings included

STL125JIG/110 is a compact socket welding machine for HDPE, PP and PP-R, PVDF, PB OD 2" ÷ 5" (standard composition steel clamps from Ø 2" to 5"; on request from Ø 1/2" to 2" STL125LKIT1202). The machine shows a steel frame that can be used as a support to the aligning body; the unit distinguishes itself by being able to work in tight spaces, after a swift releasing manoeuvre of the frame.

The machine has two trolleys, a fixed and a movable one, with practical closing handwheels in order to ensure a perfect grip in between clamp and pipe/fitting. The machine also features steel auto-centering clamps: a special clamp for the fitting, and a couple of paired clamps designed to keep the pipe in position. The trolley closing and opening operations are performed by a “mutual” starter. The special fittings clamp is placed on the fixed trolley. Whenever the type of work requires a different clamping configuration, it is rather easy to unlock and change the machine’s operativeness.

Compostition: Machine body complete with clamps and frame - NPCCE125/110 hand socket welder - Socket welder fork support - Clamps for ø 2" ÷ 5" - Transport case for socket welder and sockets & spigots - Transport case for machine body - Sustaining handle and tool kit

On Request:Steel clamps from Ø 1/2"÷ 2"

STL125JIGBASIC/110 Basic kit for STL125JIG/110 composed by machine body complete with clamps and frame and transport case.

| MODEL |

STL125L/110 |

STL125/110 |

STL125JIG/110 | STL125JIGBASIC/110 (*) |

|---|---|---|---|---|

| Dminal size range (IPS) | 2" ÷ 5" |

3/4" ÷ 5" |

2" ÷ 5" | 2" ÷ 5" |

| Power supply | 110V - 1400W | - | ||

| Dimensions machine | 24"x26"x24" | 42"x33"x22" | 6.8"x1.9"x 15.5" H | - |

| Dimensions transport case | - | 60"x31"x51" | 19.2"X13.5"X6.6" | 19.2"X13.5"X6.6" |

| Weight | 59 lb | 220 lb | 34 lb | 21 lb |

| Working temperature | 500°F (± 32°F) | 356° ÷ 536°F | 500°F (± 32°F) | - |

| Outside temperature range | 12°F ÷ 104°F | 23°F ÷ 104°F | 23°F ÷ 104°F | - |

|

Die pairs bushings |

Included (2"÷5") |

Included (3/4"÷5") |

Included (2"÷5") |

- |

| amps |

Included (2"÷5") Optional 1/2" ÷ 2" (STL125LKIT1202) |

- |

Included (2"÷5") Optional 1/2" ÷ 2" (STL125JIGRID1202) |

Included (2"÷5") |

(*) Article includes transport case + welding machine body with frame (socket welder and die pairs bushings not included)

MULTIFUNCTION AUTOMATIC WELDING UNIT FOR ELECTROFUSION FITTINGS

- description

- details

- download

These machines was designed for the welding of all electrofusion fittings.

During the welding cycle, the large backlit display shows the heating time, power consumption, voltage and energy used.

The welding unit can be operated in seven different languages (Italian, English, French, Spanish, German, Dutch and Portuguese) and have the capacity to store the parameters of 10.000 welding cycles on the external support.

The SPECIFIC internal software ALLOWS users to:

• DOWNLOAD WELDING REPORTS

• RECORD THE TRACEABILITY OF THE FITTING

• FIND THE GPS COORDINATES OF THE FITTING

• TEST THE PRESSURIZED FLUID DISTRIBUTION NETWORKS

The Welding data (time and voltage) are entered with a barcode scanner (conforming with ISO 13950) or manually by Illuminated display with 4 lines, 20 characters each.

Basic equipment supplied with the welding unit: User’s handbook on hardware support and quick guide on paper • USB key (4GB) for data download (welding report and pressure test) • Shipping box • Scanner for barcode input • Adapters with ø4,7 mm pins

Additional equipment • 00GPS: Global Positioning System • 00SENS: Pressure test unit

| MODEL |

E9001/110 SSEL8404/110 |

E9001L/110 SSEL8404L/110 (Light Version) |

|---|---|---|

| Nominal size range (IPS) | 1/2" ÷ 24" |

Couplers 1/2" ÷ 6" Saddles All Sizes |

| Fitting working range up to | 100 Amp. | 40 Amp. |

| Welding cycles memory | 10.000 | |

| Pressure tests memory | 8 memories wit 500 parameters | |

| Power supply | 115V - 50Hz/60Hz | |

| Maximum power | 2500 VA | 1000 VA |

| Output voltage | from 5 to 42V | |

| Power cable | 13.1 ft | |

| Welding cable | 13.1 ft | |

| Connectors | ø4mm + adapters ø4.7mm | |

| Dimensions | 13"x18"x 8" H | 11"x12"x 6" H |

| Weight | 55.44 lb | 29.00 lb |

| Working temperature | from 0°F to +131°F | |

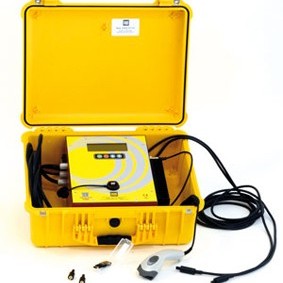

AUTOMATIC MULTIFUNCTION WELDING UNIT INCORPORATED IN CASE

- DESCRIPTION

- DETAILS

- DOWNLOAD

The new model of automatic welding units are incorporated in the most innovative waterproof case (PELI).

The case is watertight, waterproof, sand-proof, dust proof and able to with stand harsh environments and shocks. It is certified to withstand termperature rating from -28 to + 194 °F and is: in fact the ideal mean of trasportation for sensitive devices.

Basic equipment supplied with the welding unit:

• User’s handbook on hardware support and quick guide on paper

• USB key (4GB) for data download (welding report and pressure test)

• Integrated shipping box

• Barcode scanner

• Adapters with ø4,7 mm pins

Additional equipment and SPARES:

• 00SENS: Pressure test unit

| MODEL |

E9001P/110 SSEL8404P/110 |

E9001LP/110 SSEL8404LP/110 (Light Version) |

E9001SL/110 (Super Light Version) |

|---|---|---|---|

| Nominal size range (IPS) |

Couplers 1/2" ÷ 16" Saddles All Size |

Couplers 1/2" ÷ 6" Saddles All Sizes |

1/2" ÷ 2" |

| Fitting working range up to | 70 Amp. | 40 Amp. | 20 Amp. |

| Welding cycles memory | 10.000 | - | |

| Pressure tests memory | 8 memories wit 500 parameters | - | |

| Power supply | 115V - 50Hz/60Hz | ||

| Maximum power | 2000 VA | 1500 VA | 500 VA |

| Output voltage | from 5 to 42V | ||

| Power cable | 13.1 ft | 9.0 ft | |

| Welding cable | 13.1 ft | 6.5 ft | |

| Connectors | ø4mm + adapters ø4.7mm | ||

| Dimensions | 20"x17"x 9" H | 20"x16"x 8" H | 8.2"x4.5"x 7" H |

| Weight | 44.0 lb | 35.00 lb | 16.00 lb |

| Working temperature | from 0°F to +131°F | ||

MANUAL WELDING UNIT FOR ELECTROFUSION FITTINGS

- DESCRIPTION

- DETAILS

- DOWNLOAD

The welding unit was designed for the welding of all electrofusion fittings.

The welding data (time and voltage) are entered only manually and the welding data are not registered.

The welding unit can be operated in seven different languages (Italian, English, French, Spanish, German, Dutch and Portuguese).

During the welding cycle, the large backlit display shows the heating time, power consumption, voltage and energy used

Basic equipment supplied with the welding unit:

• User’s handbook

• Shipping box

• Adapters with 4,7 mm pins

| MODEL |

E8500/110 |

E8500L/110 (Light Version) |

|---|---|---|

| Nominal size range (IPS) | 1/2" ÷ 12" |

Couplers 1/2" ÷ 6" Saddles All Sizes |

| Fitting working range up to | 80 Amp. | 40 Amp. |

| Welding cycles memory | not available | |

| Pressure tests memory | not available | |

| Power supply | 115V - 50Hz/60Hz | |

| Maximum power | 2000 VA | 1000 VA |

| Output voltage | from 5 to 42V | |

| Power cable | 9.8 ft | |

| Welding cable | 9.8 ft | |

| Connectors | ø4mm + adapters ø4.7mm | |

| Dimensions | 13"x19"x 8" H | 12"x13"x 6" H |

| Weight | 44.0 lb | 34.00 lb |

| Working temperature | from 0°F to +131°F | |

MULTIFUNCTION -SMART- WELDING UNIT INCORPORATED IN CASE

SMARTWELD SMARTWELDL SSEL8404P SSEL8404LP

- DESCRIPTION

- DETAILS

- DOWNLOAD

|

MODEL |

SMARTWELD/110 |

SMARTWELDL/110 SMARTWELDLIGHT/110 (Light Version) |

|

Nominal size range (IPS) |

Couplers 1/2" ÷ 16" Saddles All Size |

Couplers 1/2" ÷ 6" Saddles All Sizes |

|

Fitting working range up to |

70 Amp. |

40 Amp. |

|

Welding cycles memory |

10.000 |

|

|

Pressure tests memory |

8 memories wit 500 parameters |

|

|

Power supply |

|

|

|

Maximum power |

2000 VA |

1500 VA |

|

Output voltage |

from 5 to 42V |

|

|

Power cable |

13.1 ft |

|

|

Welding cable |

13.1 ft |

|

|

Connectors |

|

|

|

Dimensions |

23.8"x18.3"x 12" H |

20"x16"x 8" H |

|

Weight |

44.0 lb |

35.00 lb |

|

Working temperature |

from 0°F to +131°F |

|

- NIRON

Potable Water and HVAC Applications - Flextite Compressed Air Systems

- ELOFIT Gas & Water Installations

- SMARTFLEX

GASOLINE STATIONS - Tools

Nero by Niron | Polypropylene Pipes and Fittings with UV Protection

Niron All Pro | Innovative Preinsulated PP-RCT Pipe and Fitting

ELOFIT | HDPE Electrofusion Fittings and Special Components for Water and Gas under Pressure

ELOPRESS | Complete range of Compression Fittings for the Distribution of Drinking Water and Alimentary Fluids

SMART CONDUIT | Non-hydroscopic composite piping system designed to contain electrical and communication cables in hazardous environments

Oiltech | Non-hydroscopic composite piping system designed to contain electrical and communication cables in hazardous environments